![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

69 Cards in this Set

- Front

- Back

|

Guards on a bench grinder should cover: |

2/3 of the wheel |

|

|

The gap between the tool rest and the grindstone on a bench grinder should never be more than: |

1/8" |

|

|

A grinding wheel is classified by: |

Size and type of abrasive and the type of bonding agent |

|

|

A safety specification to consider when selecting a grinding stone or disk is |

The RPM rating of the stone or disc |

|

|

A dressing tool is used for |

Refacing the surface of grind stones |

|

|

Bouncing or heavy vibration of the workpiece when grinding are indications that the grindstone is: |

Out of round |

|

|

Before installing a new grindstone you need to |

Check the wheel for cracks |

|

|

The flutes of a drill bit: |

Form the cutting edges on the point Allow chips to escape Cause the chips to curl Permit cutting oil to reach the cutting edges |

|

|

The web of a drill bit |

Separates the flutes Is the supporting section of the bit Gradually increases in thickness throughout its length |

|

|

The risk of the drill bit grabbing the work or breaking |

Increases as the bit breaks through the work piece |

|

|

A v block should be used when drilling holes in |

Round material |

|

|

Hand drills are rated by |

Size of the Chuck |

|

|

Tapered shanks are most common on which drill bits |

Large |

|

|

Slots in the drill press table are provided for |

Fitting jigs to the table |

|

|

A magnetic base drill press is an advantage on |

Holes are drilled in the vertical plane |

|

|

Forming steel plate into cylinders is a process known as |

Rolling |

|

|

The main reason for using templates when forming steel is to |

Maintain accuracy |

|

|

Before using a power brake, it is good practice to |

Confirm the machine settings |

|

|

The power tool that is best suited for creating intricate shapes and multiple bends is |

Power Bender |

|

|

Trip hammers are a good tool for |

Sharpening bucket teeth |

|

|

What two factors must be considered when setting the blade clearance on a power shear |

Material type and thickness |

|

|

One advantage of a vertical band saw is that it? |

Can be used to cut curves |

|

|

When cutting with a horizontal band saw it is possible to |

*Cut several pieces at the same time *Cut a variety of structural shapes *Start the cut and then go work on something else |

|

|

A notcher is a cutting tool found on |

An iron worker |

|

|

Safe cutting of l-shaped structures in a cut-off saw requires |

One vertical leg of the l-shape against the stationary block of the clamping device |

|

|

Power positioner is range in size from small top top versions to large industrial versions. True or false? |

True |

|

|

The shape, size or length of an object being welded on the positioner may require the use of what to help it rotate easily |

Counterweights Pipe stands |

|

|

What processes can a power position be used with? |

Manual Semi-automatic Automatic |

|

|

The safest way to use a wrench is to |

Pull on it with study pressure |

|

|

A combination square consists of |

A square head A protractor They sent ahead |

|

|

A thin rule has an advantage over a thick rule when |

Accuracy is a priority |

|

|

A good tool for accurately transferring measurements is a |

Set of dividers |

|

|

The size of pliers is determined by |

The overall length of the tool |

|

|

A bar clamp has an advantage when |

Clumping over great distances |

|

|

A 32 teeth per inch hacksaw blade is the best choice for cutting |

Thin stock |

|

|

Clamping the work piece between two pieces of wood is an effective way to hacksaw |

Thin material |

|

|

Files are classified by the |

Length, shape and cut |

|

|

Serrated blade snips have an advantage over tin snips when |

Cutting smaller more intricate patterns |

|

|

Tin snips are sized according to the |

Overall length of the tool |

|

|

The cutting edge of a cold chisel should be prepared to ____ degree angle for most materials and up to___ degrees for very hard materials |

60 90 |

|

|

How are open and wrenches sized? |

By measuring the distance across the flats |

|

|

An adjustable wrench is recommended when |

A proper fitting wrench is unavailable |

|

|

How high are angle grinders typically rated to? |

12000 RPM |

|

|

Portable hand drills have a chuck size that can range from |

1/4 to 3/4 in |

|

|

A _____ ___ is meant for precise work on holes up to approximately 1/ 2 inch diameter |

Sensitive drill |

|

|

A typical upright drill press can drill holes between |

1/2 to 4 inches |

|

|

A magnetic drill is equipped with either ____ or ___ three jaw chuck |

1/2 3/4 |

|

|

What are the three types of drill Chuck's? |

Keyed drill chuck Keyless Drill socket and sleeve |

|

|

Which drill Chuck is the most common? What size is do they come in? |

Three jaw 1/4 to 3/4 in |

|

|

____ chucks are operated by manually turning and external collar. These chucks are often found on battery powered hand drills. |

Keyless |

|

|

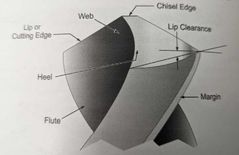

Twist drills consist of three main parts? |

The shank The body The point |

|

|

What are the two types of shanks for twist drill bits? |

Straight Taper |

|

|

In reference to drill bits,____ shanks are generally used on drills up to 1/2 inch diameter. |

Straight |

|

|

____ shanks are found on drills larger than 1/2 inch diameter |

Taper |

|

|

The body of a twist drill has two ____ flutes |

Helical |

|

|

What are the functions of the flutes on a drill bit? |

*curl the chips as they are cuts *Carry the chips out of the hole *Provide a passage for cutting fluid and coolant *Form the cutting edges on the points |

|

|

The ___ of the twist drill is where all the cutting action takes place. |

Point |

|

|

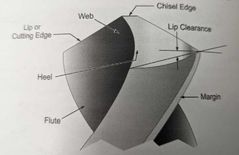

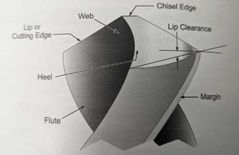

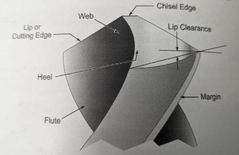

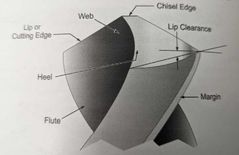

The geometry of the points on a twist drill is defined by the: (3) |

Cutting edge Chisel edge Lip clearance |

|

|

The ____ or ___ ___ extends from the chisel edge to the margin and is the portion of the points that does the cutting. The diameter of a twist drill is measured across its _____ |

Lip or cutting edge Margins |

|

|

The .... ...... Is the portion remaining between the flutes. It does not cut and should be a smallest possible |

Chisel edge |

|

|

.... Are the helical grooves around the drill that allow for coolant and chip removal? |

Flutes |

|

|

.. ......... Is provided by grinding the heel lower than the cutting edge. Without this clearance, the twist drill is not able to advance into the workpiece |

Lip clearance |

|

|

The... Is the thin portion in the centre of the drill. This forms the chisel edge and increases in thickness towards the shank |

Web |

|

|

Twist drills are manufactured with the standpoint geometry with a drill point angle of ... |

118° |

|

|

Using an increased rail point angle of ... And the reduced lip clearance of.. is better for drilling stainless steel |

135° 8° |

|

|

For other materials like plastic or non-ferrous materials you should drill with a point angle of ... to ... With a lip clearance angle up to ... |

60 to 90 12° |

|

|

When using an iron worker to punch holes, as a rule of thumb do not punch material thicker than .... |

One punch diameter |

|

|

When using an iron worker, failure to check ..... And ..... Alignment can cause them to shatter and potentially cause a serious personal injury |

Punch and die |

|

|

The ...... Is used to cope or block l shapes, c. Shapes, or other structural shapes for cross member fits unforgotten v. Notches to form .... Joints in L shapes. |

Notcher 90° |