![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

30 Cards in this Set

- Front

- Back

|

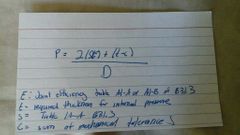

What is the formula for MAWP? |

|

|

|

What is the coefficient Y and where would you find it? |

Y is the temperature coefficient, you will find it in B31.3, Table 304.1.1, pg 22 |

|

|

Local PWHT may be sub'd for 360 degree banding on local repairs on all materiLs, provided the following precautions and requirements are applied |

A preheat of 300 degree F or higher as specified by specific welding practices are maintained while welding |

|

|

What is the coefficient W, and where would you find it? |

Weld joint reduction factor, see b31.3, Table 302.3.5, pg 20 |

|

|

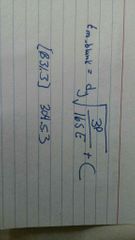

What is the formula for determining the Blank minimum thickness? |

|

|

|

Where would you find the piping allowable stress in the code books? |

ASME B31,3, Table A-1 |

|

|

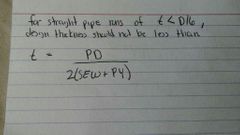

Required thickness for piping systems is determined by what formula? |

|

|

|

Detection of interior surface ID breaking planar flaws when inspecting for the external surface OD, the owner/user shall specify... |

UT Inspection performed by, QUTE |

|

|

Who obtains thickness measurements? |

Authorized Inspector or examiner |

|

|

Who is responsible to the owner/user for materials, equipment, quality control and workmanship necessary to repair piping systems? |

Repair organization |

|

|

Who evaluated and/or accepts examination results? |

Authorized inspector |

|

|

What causes mechanical fatigue? |

Cyclical stresses |

|

|

What PWHT temperature could prevent caustic stress corrosion cracking for Carbon Steel piping? |

1150 deg F, API 571 part 4.5.3.6 |

|

|

What materials have a prominently at risk to brittle fracture? |

CS, low alloy and 400 series SS |

|

|

What failure mechanisms have an appearance of straight/non-branching cracks with little to no plastic deformation? |

Brittle Fracture |

|

|

What failure mechanism is dagger - shaped, transgranular and oxide filled? |

Thermal fatigue |

|

|

What failure mechanism occurs in the crevice between two materials? |

Galvanic corrosion [API 571 4.3.15] |

|

|

What failure mechanism is characterized by cup shaped pits |

Microbial Induced Corrosion [API 571 4.3.8.5] |

|

|

What failure mechanisms is characterized by surface highly branched crazed cracks? |

CL-SCC [API 571 4.5.1.5] |

|

|

What is the preffered inspection and monitoring methods for CL-SCC? |

Phase Analysis Eddy Current or PT |

|

|

Nickel content of an alloy has a major effect on the resistance of a material from environmental cracking. Alloys w/ at least ___ % of nickel content are highly resistant from environmental cracking |

35% [4.5.1.3 (1)] |

|

|

Brittle fractures occur due to? |

Operating temperature below the ductile-to-brittlr transition temp |

|

|

ASME Section VIII had limited restrictions on notch toughness (brittle fracture) prior to what edition |

1987 [API 571 4.2.7.4] |

|

|

Atmospheric corrosion is most severe in? |

Marine environments [API 571 4.2.7.4] |

|

|

Which of the following is a means to prevent/mitigate thermal fatigue |

Reduction of stress concentrators [API 571 4.2.7.4] |

|

|

Fatigue cracking caused by high cycle (high frequency) can be difficult to detect because... |

Once cracking begins it only takes a few more cycles to fail [API 571 4.2.16.7 (d)] |

|

|

What do you get from Table A-1A and what page number of B31.3 is it on? |

You get the joint quality factor for casting systems. Pg 334 of ASME B31.3 (2016) |

|

|

What do you get from Table A-1B and where do you find it? |

Joint quality factors for piping, page 335 |

|

|

AUX small bore piping is defined as.. |

Piping that can be isolated from primary piping systems |

|

|

Why is it not possible to use statistical analysis of thickness data to assess corrosion rate and remaining life? |

Significant localized corrosion is unpredictable |