![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

14 Cards in this Set

- Front

- Back

How to prevent warping of a long thin shape printed horizontally |

- slow down printing at first layer - use heated bed to allow for better adhesion - minimise contact with cool air -apply glue or blue painter's tape on bed -increase squish for first layer (decrease distance between bed and nozzle) |

|

|

3D printing is a form of what type of manufacturing ? |

Additive manufacturing - starts off with nothing and builds up on platform. Eg brick wall. |

|

|

Subtractive manufacturing examples |

Marble statue or wood carving. Metal which is then milled away. |

|

|

Advantages of 3D printing |

Customisation Complexity Tool-less Sustainable/environmentally friendly |

|

|

Disadvantages of 3D printing |

Limited materials Questionable accuracy Manufacturing limitations Size limits |

|

|

There are 3 categories for additive manufacturing |

Selective binding Selective solidification Selective deposition |

|

|

Describe selective binding |

Make the 3D printed object from a powder (metal or gypsum) and applying agents, laser or heat to fuse the powder's particles together. |

|

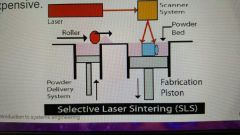

Selective laser sintering |

A type of selective binding 3D printing technology. Very delicate and complex prints can be created. There is a bed of power and the laser hardens the top layer in whatever shape is required. Another layer of powder is rolled on to the current form. These printers tend to be expensive. |

|

|

Describe selective solidification |

Makes a solid object from a vat of liquid by selectively applying energy to solidify the liquid one layer at a time. The build platform moves down into the liquid one layer at a time (or pulls up out of the liquid in some cases). |

|

|

The materials used in selective solidification |

UV light is used to solidify a resin, or digital light projection (DLP) imager. |

|

|

Disadvantages of selective solidification |

The resin needs to be cured afterwards, The liquid resin can be messy to deal with. |

|

|

Describe selective deposition |

Allows you to place the material where you want it. Eg the Dremel filament-based printers. A filament is melted and deposited on a surface. The process is called Fused Deposition Modelling FDM. |

|

|

Polyjet 3D printers |

A selective deposition application where the resin is printed by an inkjet which is then UV cured. |

|

"Raft" |

A raft is the first layer that is put down by the 3D printer in filament-based printing. To remove the object from the bed, squeeze a spatula between the bed and the raft and pry it apart. |